Temperzone OUC or Outdoor Unit Control Board

A short history of the Temperzone OUC board

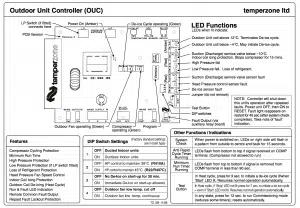

The OUC or Outdoor Unit Controller board was used in almost every Temperzone air conditioning unit from 2005 – 2012/13. This simple but effective control board was an efficient solution to control the outdoor unit operations including Outdoor Fan control (head pressure), Compressor operation and basic safety fault lockouts. The OUC has complete independent control of the outdoor unit to allow fixed-speed (non-inverter) air conditioning operation control. The OUC board has since been superseded by the UC6, UC7 or UC8 boards in the newer Temperzone units.

Basic Functions

The OUC board, installed in nearly all Temperzone outdoor units of its era, had 2 main inputs from the indoor unit; a compressor call/start input and a heat/reversing valve input. Some Temperzone models had twin compressors and the OUC had the capacity to stage these compressors individually as required. These inputs were the only communication between the indoor and outdoor units and were generally 240v AC.

On the right-hand side of the Temperzone are the fault LEDs. These are yellow LED lights situated next to specific faults to allow you to ascertain what fault the unit has stopped on. Faults include High Pressure (H.P.) faults, Low Pressure (L.P. fault), Frost faults and sensor faults. The top 3 lights show the defrost start or stop operation which is explained later in this post.

The power LED in the middle of the OUC board shows 240v AC power is present on the board. This does not mean the unit is operational but only that the P terminal has 240v AC applied. If 240v AC is present at the P terminal and the power LED is not lit, the board is faulty and will need to be replaced.

When the unit is initially powered up or powered up after the power has been switched off, the OUC board will complete an initialisation mode. LEDs on the right-hand side of the board will flash in a pattern from the outside to the centre and back for 15 seconds. Nothing will operate until this system check is complete. This is then followed by a 45-second delay in which no lights will be displayed unless the unit had faulted when last powered up.

Main Features of the Temperzone OUC board

- Compressor cycling protection

- Minimum run time

- High pressure protection

- Low-pressure protection (if LP switch fitted)

- Loss of refrigerant protection

- HP fan speed control

- Indoor coil icing protection

- Run and fault LED indication – Remote common fault output (if extra relay board fitted)

- Repeat fault lockout protection

- Fault light retention on startup.

Outdoor Unit Head Pressure Control

The Temperzone OUC board varied the voltage to the fan speed wire to control the outdoor fan motor speed. This allowed the OUC board to keep the head pressure up on the cooling cycle, 45°C on R22 refrigerant and 38°C on R410a refrigerant, to ensure the refrigerant is kept at a constant pressure ensuring maximum capacity. The voltage to the fan motor is adjusted depending on the temperature sensor located in the outdoor coil.

Defrost Control

Defrosting is an important task, especially during cold Adelaide winters, to ensure the unit can operate efficiently during low ambient temperatures. The defrost operation ensures the outdoor unit coil doesn’t block with ice which reduces airflow and performance of the unit. The OUC board turns the outdoor fan motor off during the defrost cycle to ensure faster and more effective defrost. The outdoor coil temperature sensor monitors the temperature of the coil and will initiate the defrost operation when the temperature reaches below -5 deg C.

When the unit is on the heating cycle, the OUC board will utilise the Start/Stop LEDs on the top right-hand side of the board. This will show the current temperature of the outdoor coil temperature sensor and how close the unit is to initialising the defrost cycle.

Compressor Operation/Cycling

Fixed speed air conditioning units do not vary the speed and capacity of the compressor during operation, these types of units are either 100% operational or completely stitched off. The OUC board is designed to send 240v AC to the compressor contactor when heating or cooling is required. This output is prevented when the unit is within its short cycle delay cycle and held on during its run-on cycle.

The short cycle delay built into the Temperzone OUC board prevents the compressor from stopping and then starting without a 3-minute time delay between each operation. If the compressor doesn’t have time to equalize the pressure between the high-pressure side and the low-pressure side, damage can be caused to internal components within the compressor during start-up. The OUC board will flash lights from bottom to top continuously until this mode is finished.

The run-on cycle prevents the compressor from switching off within 5 minutes of switching on. This prevents the compressor from stopping and starting violently and helps oil return to the compressor. The OUC board will flash lights from top to bottom continuously until this mode is finished.

Fault Display (Safety Faults)

As mentioned earlier in the post, the OUC board displays safety lock-out faults if activated during operation. Generally, the OUC board will need to see these faults 3 times before the board will lock out on the fault and prevent the unit from operating. These faults will also be displayed for 45 sec if the power to the unit has been switched off and then back at the outdoor unit or main circuit breaker.

Frost Fault

Indoor unit is icing up on cooling. If the Red sensor reads a predetermined low temperature on the large suction pipe, the unit will shut down for 15 minutes. If this happens 4 times in a row, the unit will lock out on a frost fault.

L.P (Low Pressure) Fault

Measures the difference between the Red and Yellow sensors on cooling and the discharge temperature (red sensor) on heating. On the cooling cycle, the unit measures the superheat using both the Red and Yellow sensors. If the unit superheat (temperature difference between the 2 sensors) is greater than 19°C, the unit will fault on L.P fault. On the heating cycle, if the OUC board measures hot above 100°C, indicating a lack of refrigerant to the compressor, the unit will trip on L.P. fault. Some OUC boards have an inbuilt L.P pressure switch. This will overrule the temperature sensors and trip the unit on L.P fault if the pressure gets too low. Ensure there is not a manual overload button on this pressure switch that needs to be reset.

H.P (High Pressure) Fault

This fault is solely measured by the pressure switch installed on the OUC board. These are the 2 Orange wires connected to the top of the OUC board. If the pressure is too high during operation the unit will lock out on H.P fault and the compressor will stop running for at least 3 minutes. After 3 times, the unit will lock out on H.P fault and prevent unit operation. Ensure there is not a manual overload button on this pressure switch that needs to be reset.

S/V, HPC and De-Ice Sensor Faults

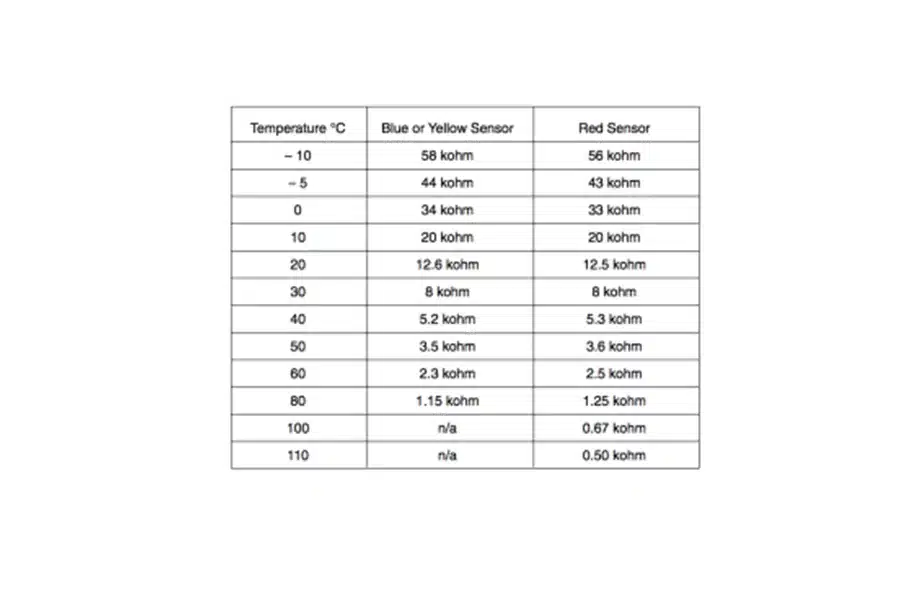

These faults are rare as the Temperzone OUC sensors hardly fail. If any of these LEDs are lit, the sensor is either a short circuit (0 ohms) or an open circuit (Infinite ohms). To test the sensors, disconnect from the OUC board and use a multimeter on the ohms setting to read the resistance of the sensors at the following temperatures below:

Replace the sensors if the ohms readings are different to those specified in the table above.

Common Faults We Have Found With the Temperzone OUC Board

The OUC board has a large application and is a simple but effective solution in fixed-speed Temperzone units. With almost 30 years of experience at T&K Airpower with Temperzone products in Adelaide, the OUC board was one of our favourites! Below is a list of the most common faults we have found with these boards and what you will need to check.

L.P Faults - Check the following:

- Refrigerant suction pressures low during operation; check for leaks

- Suction pressure switch has a manual reset that needs to be pressed

- Superheat is correct and between 2-4°C during standard operation with ambient temperatures between 27-38°C on cooling.

H.P faults - Check the following:

- Outdoor fan motor is operational and capacitors are reading correctly (cooling cycle)

- Indoor fan is operational and capacitors are reading correctly (heating cycle)

- Return air filter and indoor coil are clean (heating cycle)

Return air ductwork has not collapsed or broken internally (heating cycle) - Refrigeration circuit does not have a blockage

- Service valves are open

- Outdoor coil is not blocked/restricted (cooling cycle)

Frost Faults - Check the following:

- Indoor fan motor is operating correctly

- Indoor fan motor capacitor is reading correctly

- Filter and indoor coil are in good condition and free from blockages

- Return air duct has not collapsed or broken internally

- Suction refrigerant pressures are correct and not low

No LEDs on the OUC board. Check the following:

- Check the Isolator is switched on

- Check the circuit breaker is switched on

- Check for 240v AC between the P and N terminal on the board. If there is 240v AC and no LEDs, replace the board as the built-in transformer has failed

Cooling operation does not work but heating does. Check the Following:

- Check the Compressor input and the Heating input are correct. Generally this fault occurs when the inputs are crossed over and the heat input is wired to the cool input and vice versa. Common when the indoor unit controller has been recently replaced.